- Product Catalog

- EPS Pre-expander series

- EPS Shape Moulding Machine Series

- EPS Block Moulding Machine Series

- EPS Cutting Machine Series

- EPS Mould & EPS Products

- EPS Recycling System

- Centre Vacuum System

- Auxiliary Equipments

- Accessories

- Factory Layout

Contact Us

-

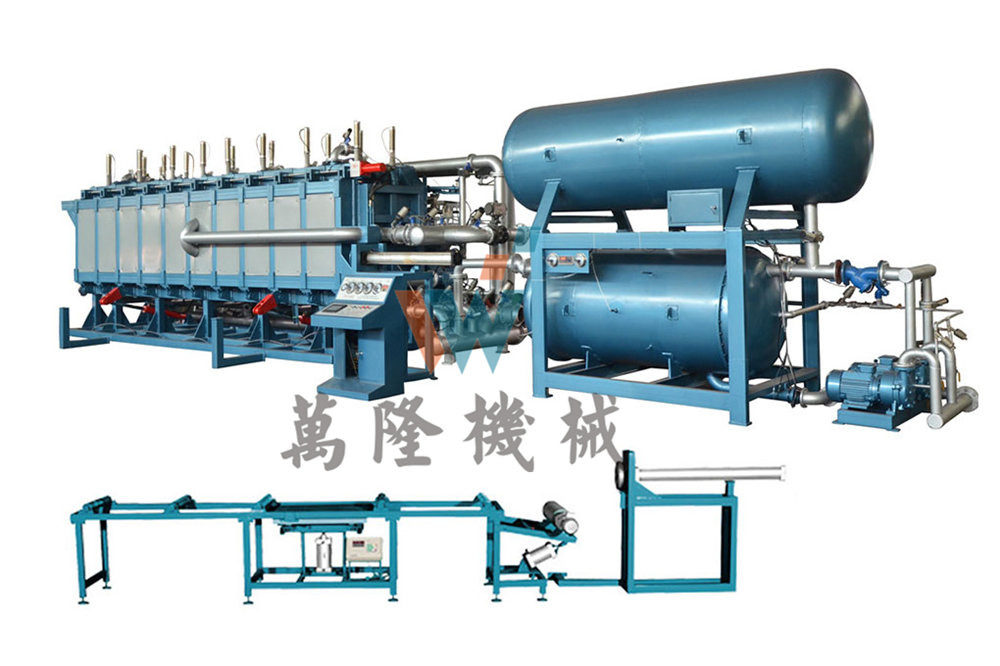

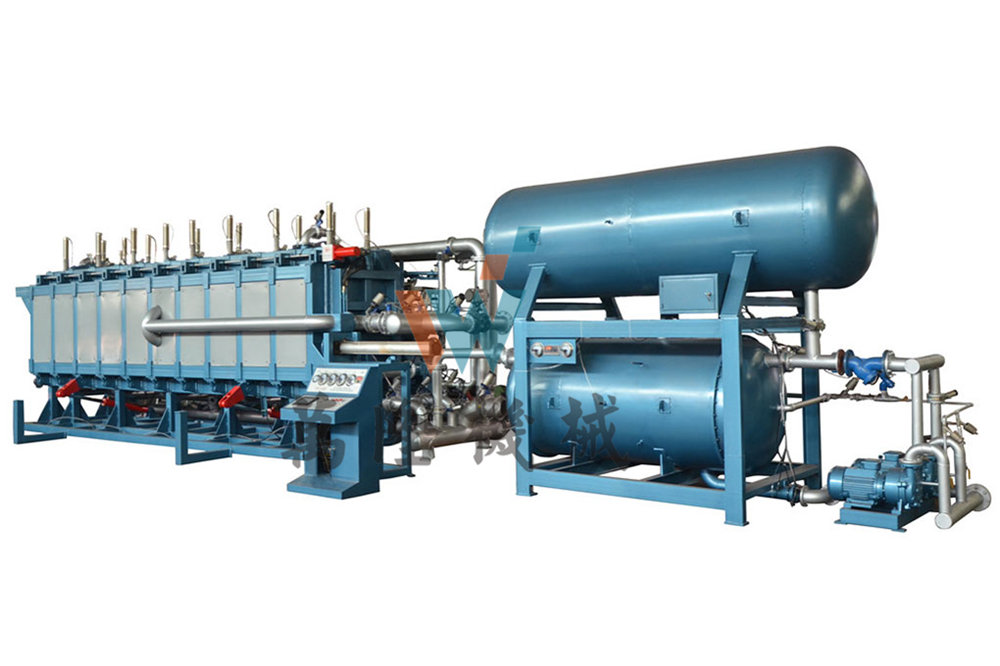

Styrofoam Vacuum Block Moulding Machine

Styrofoam Vacuum Block Moulding Machine -

Polystyrene block moulding machine

Polystyrene block moulding machine -

EPS block molding machine

EPS block molding machine -

EPS block making machine

EPS block making machine -

EPS thermocol block making machine

EPS thermocol block making machine -

Expandable polystyrene machine 2M

Expandable polystyrene machine 2M -

Expandable polystyrene machine

Expandable polystyrene machine -

EPS vacuum block moulding machine

EPS vacuum block moulding machine -

EPS polystyrene vacuum block moulding machine

EPS polystyrene vacuum block moulding machine -

EPS foam block machine for panel

EPS foam block machine for panel -

EPS foam thermocol block machine

EPS foam thermocol block machine -

Auto Block Moulding Machine with adjustable template

Auto Block Moulding Machine with adjustable template

EPS Block Moulding Machine:

EPS Block Moulding Machine is a versatile machine that can be used for a variety of tasks. This machine can be used to produce parts such as frames, casings, and plates. The EPS Block Moulding Machine is also capable of producing complex shapes and figures that would be difficult to produce using other methods.

The EPS Block Moulding Machine is a versatile machine that can be used for many different types of plastic moulds. It is a reliable machine that is easy to use. This machine is perfect for businesses that need to produce plastic products quickly and efficiently.

EPS Block Moulding Machine is the latest developed equipment product, which is special purpose equipment for making building block making machine. The material can be fly ash, slag, gangue or other industrial waste, river sand, gravel, cement, etc. Make different sizes of hollow blocks, porous blocks, curbs, pavement blocks. If you add a color machine, you can make layer blocks.

EPS Block Molding Machine is to expand EPS raw material to required density, the machine works in a continuous way both in taking raw material and discharging expanded material.

EPS Block Molding Machine can do second and third expansion to get low density.

EPS Block Molding Machine complete with Screw Conveyor, First and second expansion loader, Expander, Fluidized bed Drier

China EPS equipment manufacturer, EPS block moulding machine

EPS block moulding machine that EPS equipment manufacturer offerd is a factory automation equipment that can produce various shapes of plastic blocks by using the injection molding process. It has high precision andfast speed, which makes the equipment ideal for producing precise parts in small quantities. The machine also has a variety of options that allow you to customize your production process.

EPS block moulding machine is the newest type of equipment for manufacturing EPS. It replaces traditional methods such as injection molding and blow molding, and has become a popular choice for making products with complex shapes. This machine can make intricate designs quickly and efficiently, making it a valuable tool in the manufacturing process.

Advantages of EPS Block Moulding Machine:

EPS blocks have complex shapes, making them difficult to produce using traditional moulding methods

The EPS block moulding machine is designed specifically for this purpose and can produce accurate and consistent parts

It is fast, easy to use and can handle large quantities of blocks with minimal effort

The machine is also highly precision and can be used for a variety of other manufacturing tasks

All parts produced using the EPS block moulding machine are guaranteed to be fit for purpose

Types of EPS block moulding machine

Types of EPS block moulding machine: There are three types of EPS block moulding machines: the horizontal type, the vertical type, and the rotary type. The horizontal type is used to produce two-dimensional products, while the vertical and rotary types are used to produce three-dimensional products. The horizontal type is the most common type of machine, and it uses a pair of rollers to press the plastic sheets against each other.

There are many types of EPS block moulding machine, each with its own advantages and disadvantages. Here are four of the most common types: horizontal shaft machines, vertical shaft machines, CNC machines, and manual machines. Each has its own unique set of features that may be important to you as a molder. Do your research to find the type of machine that best suits your needs.

Moulding is a manufacturing process that creates objects from a fluid or plastic material. There are many types of moulding machines, each with its own advantages and disadvantages. Here are four types of machines used for block moulding: die-casting machine, injection moulding machine, blow moulding machine, and thermoforming machine.

Adjustable EPS Block Moulding Machine

Adjustable EPS Block Moulding Machine full automatic machine runs stable and effective. Our machine makes the blocks with very good density and high quality. I am sure you will satisfied with it.

Looking for a reliable and efficient machine to produce EPS blocks? Look no further than the Adjustable EPS Block Moulding Machine! This unit is able to efficiently produce blocks of EPS foam, making it an ideal choice for those in need of a high-quality product. Additionally, the machine is easy to use and has a low production cost, making it an affordable option for businesses of all sizes.

Feeding system of EPS Block Moulding Machine:

The EPS Block Moulding Machine adopts a steel frame structure and a new feeding system to ensure accurate and uniform feeding, ensuring the high density of the product. So the product density is high.

Vibration system of EPS Block Moulding Machine:

The vibration system includes platform vibration and mold vibration, so the product size is very fine and the production speed is fast. First of all, synchronous vibration ensures the amplitude of the vibration table. In addition, the frequency can be changed according to different technologies. Low-frequency feeding and high-frequency vibration enable different materials to obtain the best vibration method to ensure the high quality of concrete products.

German Siemens PLC control system of EPS Block Moulding Machine:

EPS Block Moulding Machine adopts a Siemens PLC control system, which is easy to operate and greatly reduces the failure rate. So that the machine runs stably and reliably. In the automatic weighing system, the air compressor is provided with the machine. In addition, combined with the remote control system, inspection, control, and diagnosis can be realized. Therefore, the fault diagnosis system has been highly praised by customers. Finally, the man-machine interface, the control system is equipped with complete logic control, production procedures, fault diagnosis system, and remote control functions. So it does not require professionals, only a simple well-trained operator.

Hydraulic system of EPS Block Moulding Machine:

Our hydraulic pumps and valves are from China, which is famous for its high-quality products. In addition, flange connection pipes ensure convenient installation and maintenance. On the other hand, multiple pressure detection points ensure convenient detection.

Application of EPS Block Molding Machine:

The fat barrel, outside an all-stainless steel compartment, has insulation measures, reliable performance, reasonable structure, beautiful, stable quality, high production efficiency, increase 2-3 times than the average machine, low energy consumption 25%.

The EPS Block Molding Machine feed system including a feeding device and the second feeding device, a feeding device by adjusting the feed rate of transmission in order to ensure a stable feed.

EPS beads through the material, the foam into the fluidized bed dryer ( customer optional ), and then into the aging silo through the fan delivery device, complete raw foaming process, process cycle according to the second foam.

The EPS Block Molding Machine produced a more uniform density can foam density of 7-35kg/m3.

Let the steam valve, the user can choose according to need.

About EPS Block Moulding Machine Supplier / Manufacturer

WANLONG MACHINERY is a professional EPS Machinery Supplier and polystyrene machine manufacturer, We offer kinds of EPS machines, EPS molds, 3D panel machines, sandwich panel machines, assistant facilities and all kinds of EPS machine spare parts.

WANLONG MACHINERY is a leading China EPS Block Moulding Machine Manufacturer.

Our EPS Block Moulding Machine with more than 10 of the provincial high-tech products, the invention patent, utility model and appearance design patent etc. In addition, we passed the certifications of quality management system ISO9001, the products has with high efficiency, low energy consumption, stability, durability, easy maintenance, etc.

If you want to know the price of EPS Block Moulding Machine, contact us.