-

EPS polystyrene foam beeds machine

-

EPS continuous pre-expander machine

-

Automatic expandable polystyrene pre-expander machine

-

EPS polystyrene foam beeds machine

Styrofoam expander machine

Port: Hangzhou, China

Production capacity: 20 sets / month

Payment method: Letter of credit, telegraphic transfer

Model:Automation

Computerized: Computerized

Certification: CE, ISO9001:2008

Condition: New

Add To Basket

Add To Basket

PDF:

Styrofoam expander machine | expander machine | expander machine supplier

1.The machine is a special equipment for the lost foam ‘white area casting’, it is able to expanding EPS,EPP,EPMMA, etc;

2.This machine applies PLC Controller (programmable Logic Controller) and Touch Screen;

3.Unique design for steam dome reduces EPS bead moisture content;

4.This machine applies Sealed expansion barrel、Automatic Photoelectric Level Control Device to control material level,enables expansion under constant pressure, high steaming efficiency and steam saving, ensuring density of formed EPS beads minor tolerance within ±1%;

5.Mainshaft,stirring bars, inner barrel made from stainless steel;

6.Most of the main components are of world-famous brand, and reliable design makes the operation and production simpler and fault rate lower.

Styrofoam expander machine

Features:

1. 700mm Z-axis feeding height & effective travelling for heavy and thick materials.

2. Spindle rotated 180 degree, you can make 2D/3D/4D carving on curved surface, arc-surface,bending surface, larger dimension mould, statues, sculptures, cylinders and so on...

3.Powerful 9KW China HQD ATC air cooling spindle , can move 0-180 degree.

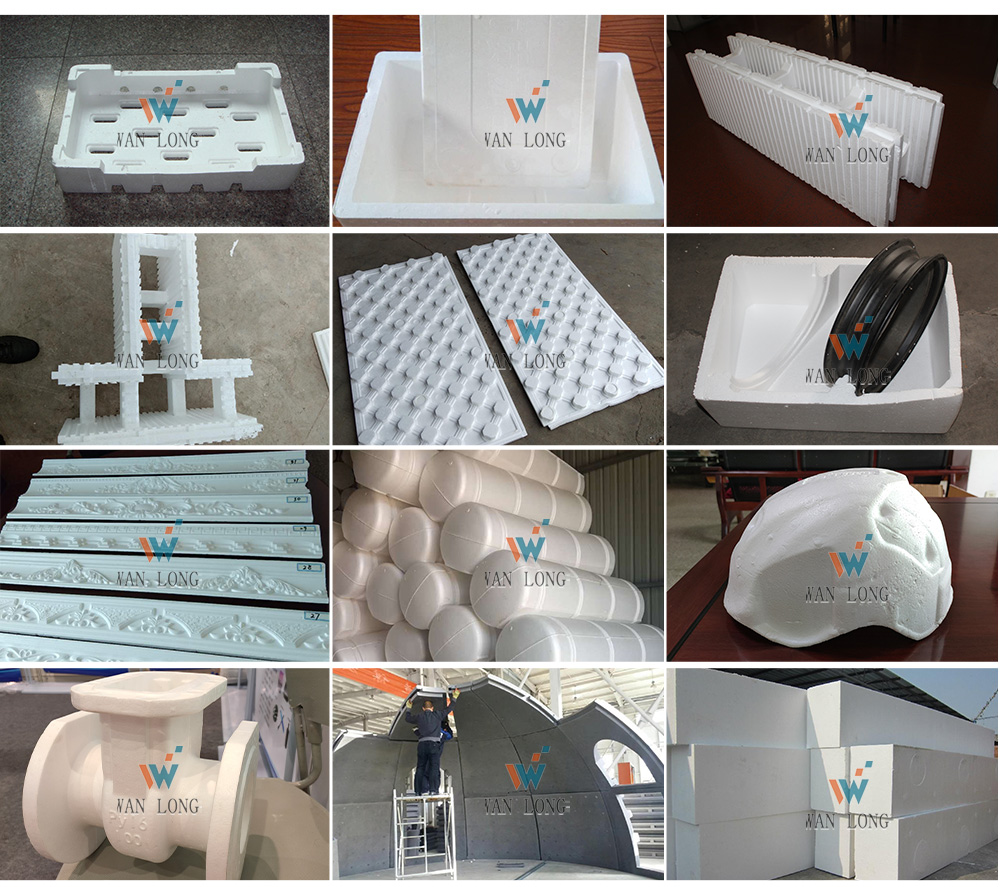

WANLONG MACHINERY is a leading Styrofoam expander machine supplier, factory, manufacturer that focuses on Styrofoam expander machine. We focus on producing high-quality products with complete specifications. The quality of our products has passed international certification and the price is affordable.

Styrofoam expander machine

When designing and developing new products according to customer needs, we strictly control quality standards while controlling production costs.

| Items | Unit /Type | EPS-JF-450 | EPS-JF-500 | ||

| Expansion Barrel | Size | mm | Ø450x700 | Ø500x700 | |

| Usable Volume | m3 | 0.1 | 0.12 | ||

| Steam | Pressure | Mpa | 0.2-0.3 | 0.2-0.3 | |

| Inlet DN | mm | 25 | 25 | ||

| Consumption | Kg/cycle | 0.6-0.8 | 0.8-1.0 | ||

| Air-Compressed | Pressure | Mpa | 0.2-0.3 | 0.2-0.3 | |

| Inlet DN | mm | 25 | 25 | ||

| Consumption | m3/cycle | 0.05-0.06 | 0.05-0.06 | ||

| Throughput | 12g/L | kg | 35 | 40 | |

| 15g/L | 70 | 80 | |||

| 20g/L | 100 | 120 | |||

| 30g/L | 140 | 160 | |||

| Density Range | g/L | 12-40 | 12-40 | ||

| Density Tolerance | % | ≤+/-1.0 | ≤+/-1.0 | ||

| Cycle Time | min | Approx. 1.2 | Approx. 1.5 | ||

| Connected Load | kw | 3 | 3 | ||

| Weight | kg | 560 | 600 | ||

| Overall Dimension | (LxWxH)mm | 3000x2100x2280 | 3000x2100x2280 | ||