-

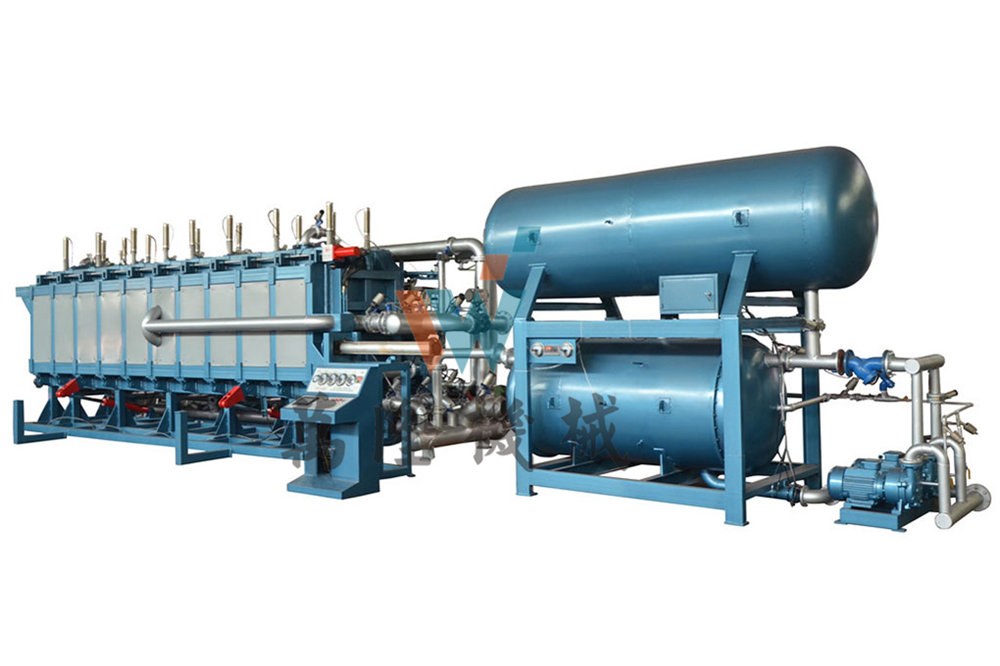

EPS block molding machine

-

Polystyrene block moulding machine

-

Automatic Air-cooling Block Moulding Machine

-

Auto Air-cooling Block Moulding Machine

-

EPS polystyrene foam beeds machine

Styrofoam Vacuum Block Moulding Machine

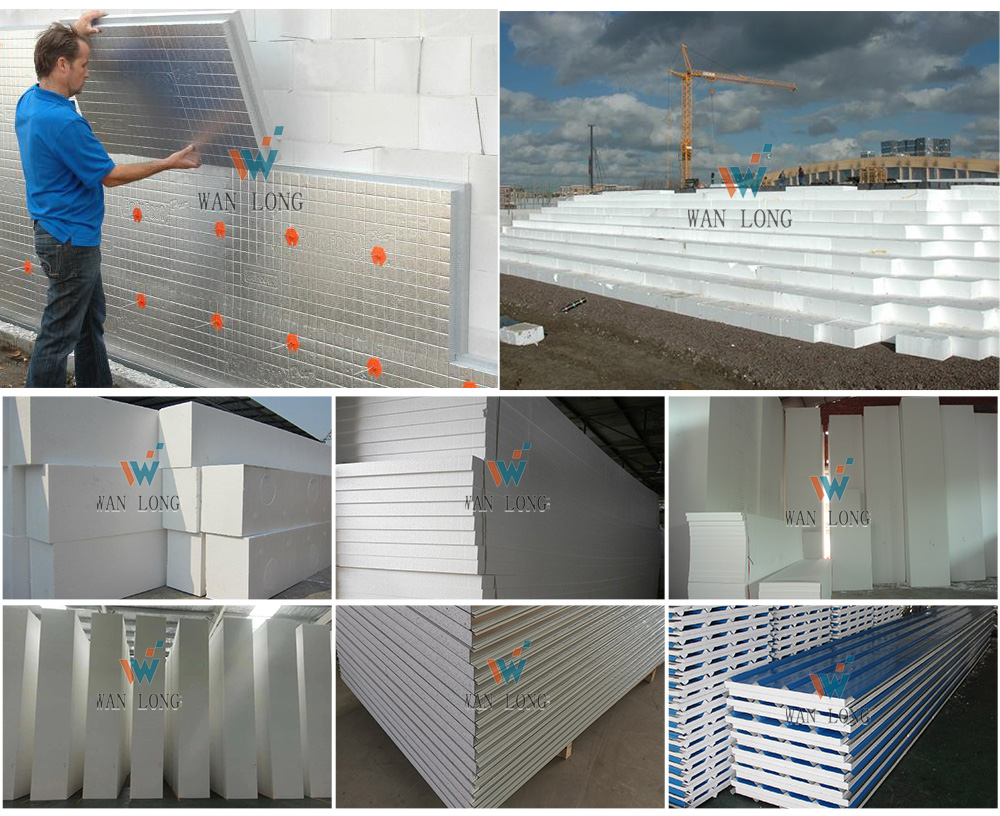

Styrofoam vacuum block moulding machines are often used in the manufacturing of products such as cups and boxes. These machines use a block of styrofoam that is heated to a specific temperature and then pressed into a desired shape. This process is often used to create products that are difficult or impossible to make using other methods.

Add To Basket

Add To Basket

PDF:

Styrofoam Vacuum Block Moulding Machine | Styrofoam Block Machine

1.The Styrofoam Vacuum Block Moulding Machine can create blocks of styrofoam up to 2x2x2 feet.

2.It is easy to use- simply plug in and turn on.

3.The machine has a built in vacuum that sucks the styrofoam into the mould.

4.This creates a block that is smooth on all sides and has no air bubbles.

5.The machine is fast- it can create a block in under 5 minutes.

6.The machine is portable and easy to store.

Styrofoam Vacuum Block Moulding Machine

Styrofoam vacuum block moulding machine is used to produce various shapes of styrofoam products. It has a great potential in the market as it is very fast and easy to operate. This machine can be used to produce products such as toys, boxes, cups and other small items..

Styrofoam vacuum block moulding machine is widely used in the food industry. It can produce vacuum blocks with various shapes and sizes. The machine can also produce different kinds of vacuum sealers.

Styrofoam vacuum block moulding machines are often used in the manufacturing of products such as cups and boxes. These machines use a block of styrofoam that is heated to a specific temperature and then pressed into a desired shape. This process is often used to create products that are difficult or impossible to make using other methods.

Styrofoam Vacuum Block Moulding Machine manufacturer/supplier/factory in China

The Styrofoam Vacuum Block Moulding Machine is a great machine for those looking for an easy way to create styrofoam blocks. It is made from durable metal, has a large work area, and can easily produce blocks up to 2 feet wide by 2 feet high.

Styrofoam vacuum block moulding machine is widely used in various industries such as Automobile, Furniture, Electronics and Medical. It is an automatic machine that uses a vacuum to remove the foam from the block. The machine can create any shape or size of styrofoam blocks.

WANLONG MACHINERY is a leading Styrofoam Vacuum Block Moulding Machine supplier, factory, manufacturer that focuses on Styrofoam Vacuum Block Moulding Machine. We have our own production workshop and design team. If you cooperate with us, we can provide you with first-hand prices.

No matter from which point of view, we are the best choice.

| Items | Unit /Type | EPS-B-2000Z | EPS-B-3000Z | EPS-B-4000Z | EPS-B-6000Z | EPS-B-8000Z | |

| Mold Size | mm | 2030*1230*1050 | 3030*1230*1050 | 4040*1230*1050 | 6100×1230*1050 | 8100*1240*1050 | |

| Block Size | mm | 2000*1200*1000 | 3000*1200*1000 | 4000*1200*1000 | 6000*1200*1000 | 8000*1200*1000 | |

| Products density range | Kg/m3 | 6-30 | 6-30 | 6-30 | 6-30 | 6-30 | |

| Throughput | min/cycle | 3--5 | 3--8 | 5--10 | 5--10 | 5--10 | |

| Steam | Pressure | Mpa | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Inlet DN | mm | 100 | 100 | 100 | 150 | 150 | |

| Consumption | kg/cycle | 30--50 | 50--70 | 60--90 | 90--130 | 120--170 | |

| Air-Compressed | Pressure | Mpa | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| Inlet DN | mm | 40 | 40 | 40 | 40 | 40 | |

| Consumption | m3/cycle | 1.5-2.0 | 1.8-2.2 | 2.0-2.5 | 2.0-3.0 | 2.5-3.0 | |

| Vacuum Cooling Water | Pressure |

Mpa |

0.4-0.6 |

0.4-0.6 |

0.4-0.6 |

0.4-0.6 |

0.4-0.6 |

| Inlet DN |

mm |

50 |

50 |

50 |

50 |

50 |

|

| Consumption |

m3/cycle |

0.4-0.5 |

0.5-0.6 |

0.6-0.8 |

0.8-1.0 |

1.0-1.2 |

|

| Power Connected | kw | 20-25 | 20-25 | 25-35 | 25-35 | 35-43 | |

| Voltage | v | 380 | 380 | 380 | 380 | 380 | |

| Overall Dimension | mm | 5800*4000*3000 | 7500*4000*3000 | 11000*4000*3000 | 14000*4000*3000 | 16000*4000*3000 | |

| Weight | kg | 6000 | 8000 | 12000 | 15000 | 17500 | |

| Note: we custom build our machines according to any customer's special requirements. | |||||||