-

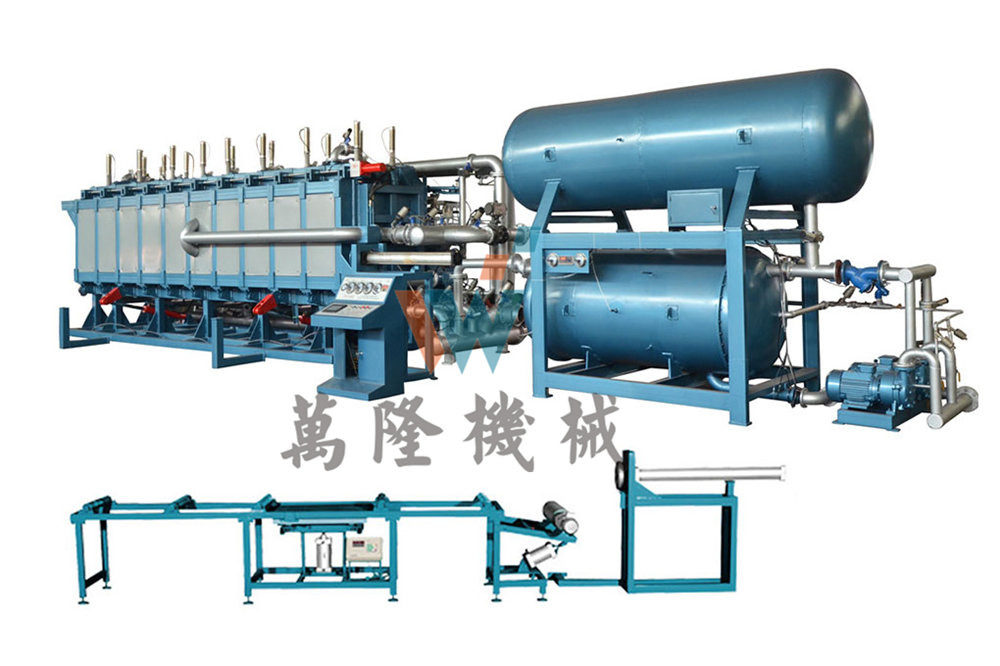

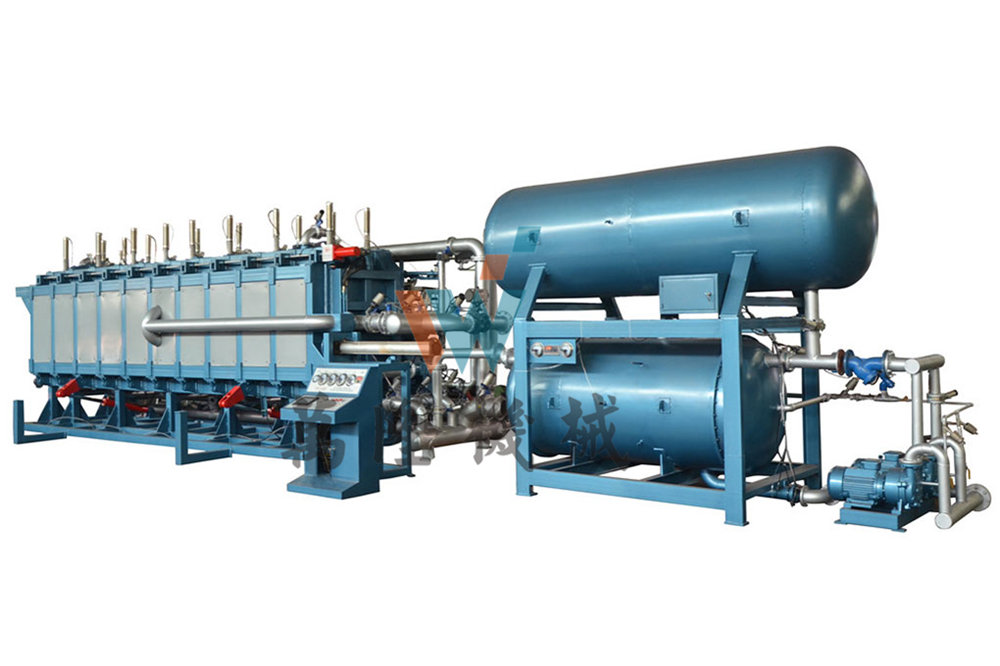

EPS vacuum block moulding machine

-

EPS polystyrene block moulding machine with adjustable template

-

Auto Block Moulding Machine with adjustable template

-

EPS polystyrene vacuum block moulding machine

-

EPS polystyrene foam beeds machine

Styrofoam Cutting Machine

Port: Hangzhou, China

Production capacity: 20 sets / month

Payment method: Letter of credit, telegraphic transfer

Model:Automation

Computerized: Computerized

Certification: CE, ISO9001:2008

Condition: New

Add To Basket

Add To Basket

PDF:

EPS Cutting Machine, Styrofoam Cutting Machine supplier

1.The main body of the machine is welded from thick-wall square tube, It can be dismantled and assembled easily;

2.The machine applies electric heating wires to cut EPS blocks;

3.The machine has Frequency-Speed Regulator to regulate the speed between 0-4m/min, to enable smooth operation, and to smoothly cut the EPS Blocks of stable dimensions;

4.The cutting machine has the Horizontal, Vertical and Edge surface cutting wires to achieve the three-dimensional (3D) cutting of the EPS Blocks, horizontal and vertical cutting can be working at the same time. The machine has mechanically controlled clutch to realize a quick return of cutting frame;

5.The machine has a special Transformer with multiple sockets for adjustment with wide adjustable range; the heat can be regulated easily.

Note: we custom build our machines according to any customer's special requirements.

EPS Cutting Machine ,Styrofoam Cutting Machine

Product Descriptions of the EPS Cutting Machine

EPS Cutting Machine is a popular material for making things like cups, plates, and other small objects. It's also sometimes used in insulation. Cutting styrofoam is a difficult process because it's very soft and doesn't hold its shape well.

There are several types of cutting machines that can be used to cut styrofoam. The most common type is a rotary cutter. This type of machine has a blade that revolves around a central shaft.

There are many things people do with Styrofoam. Some people use it to make crafts, others use it as a packing material for shipping. But there is one thing that most people don't think of: using it as a cutting material. Cutting machines can be used to cut Styrofoam into any shape or size. There are many different types of machines on the market, so it's important to choose the right one for the job.

Advantages & Features

The machine is able to cut Styrofoam with precision and ease, making the process quick and simple.

The machine is able to cut a wide range of Styrofoam sizes, making it a versatile tool for any project.

The machine's easy-to-use design means that anyone can operate it, regardless of experience or skill level.

The machine is lightweight and compact, making it easy to transport and store when not in use.

The machine's durable construction ensures that it will last for years, providing consistent performance every time.

EPS Cutting Machine,Styrofoam Cutting Machine Supplier

Styrofoam cutting machine supplier is a manufacturer and supplier of styrofoam cutting machines and other related equipment. With yeas of experience in the styrofoam industry, our machines can handle almost any type of styrofoam. We also offer custom-made machines to meet your unique needs. Contact us today for more information about our styrofoam cutting machines.

WANLONG MACHINERY is a leading Cut Eps Machine,EPS Cutting Line, Styrofoam Cutting Machine supplier, factory, manufacturer that focuses on EPS cutting machine. We have our own production workshop and design team. If you cooperate with us, we can provide you with first-hand prices.

No matter from which point of view, we are the best choice.

| Items | Unit /Type | EPS-Q-2000 | EPS-Q-3000 | EPS-Q-4000 | EPS-Q-6000 | EPS-Q-8000 | ||

| Max Block Size | mm | 2000*1300*1300 | 3000*1300*1300 | 4000*1300*1300 | 6000*1300*1300 | 8000*1300*1300 | ||

| Cutting Speed | m/min | 0-2.5 | 0-2.5 | 0-2.5 | 0-2.5 | 0-2.5 | ||

| Wire Specification | mm | Ø 0.4-0.6 | Ø 0.4-0.6 | Ø 0.4-0.6 | Ø 0.4-0.6 | Ø 0.4-0.6 | ||

| Min. Cutting Thickness | mm | 10 | 10 | 10 | 10 | 10 | ||

| Number of Operation Hot Wire Simultaneously | piece | 40 | 40 | 40 | 40 | 40 | ||

| Connected Load | kw | 7.55 | 7.55 | 7.55 | 7.55 | 7.55 | ||

| Overall Dimension | mm | 3500*2040*2400 | 5500*2040*2400 | 6500*2040*2400 | 8500*2040*2400 | 10500*2040*2400 | ||

| Machine Weight | kg | 1000 | 1100 | 1500 | 2000 | 2400 | ||

| Note: we custom build our machines according to any customer's special requirements. | ||||||||