-

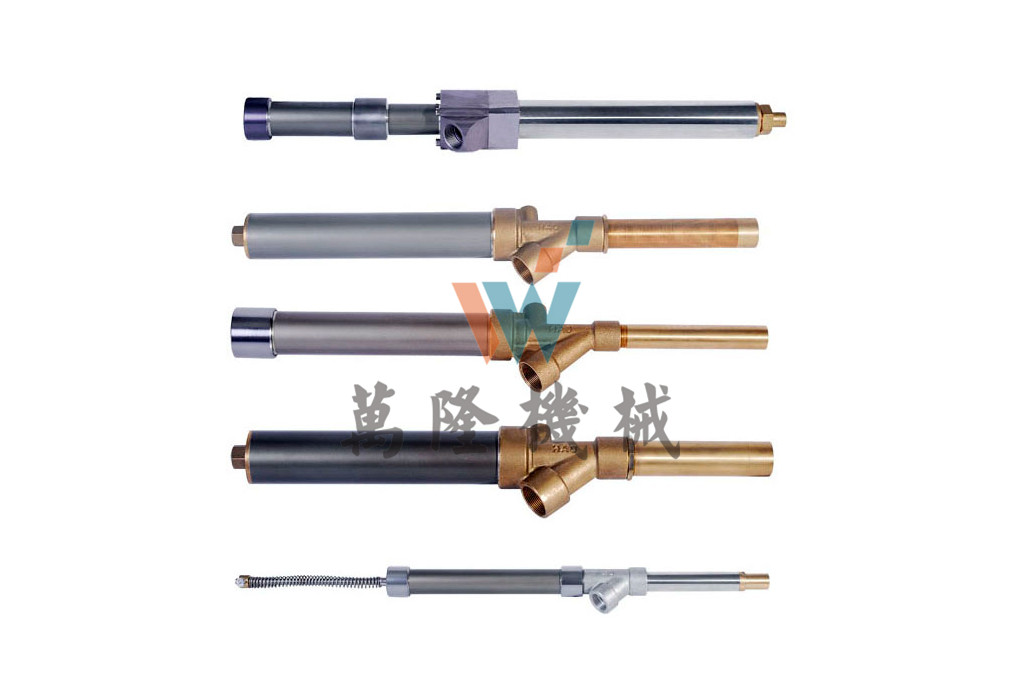

Filling gun

-

Touch screen delta

-

PLC MITSUBISHI

-

EPS polystyrene foam beeds machine

-

EPS continuous pre-expander machine

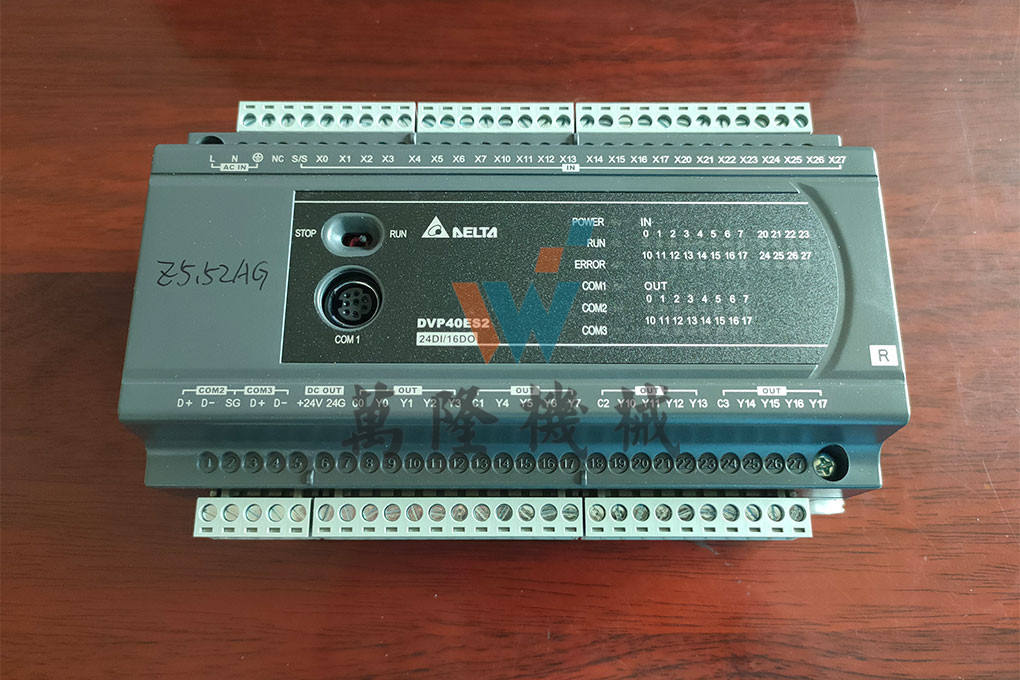

PLC DELTA

Port: Hangzhou, China

Production capacity: 3000 pieces / month

Payment method: Letter of credit, telegraphic transfer

Mould Cavity: Customerize

Plastic Material: EPS

Certification: CE, ISO9001:2008

Condition: New

Add To Basket

Add To Basket

PDF:

EPS polystyrene moulding machine | EPS moulding machine | polystyrene moulding machine

Product Description

1. Rich features and flexible system configuration in a compact size.

2. The PLC incorporates power supply, CPU, and I/Os into a single compact unit.

3. Meets the needs of a variety of user applications with options for I/O, analog, positioning, and open network expansion.

4. Faster, friendlier. Realize high expandability and high functionality.

5. For high-speed control to network support and even logging is possible.

6. FX3 series flagship model FX3U and connector type FX3UC: 2 models are available.

Our Advantages

OEM Service : Customers simply provide heat transfer, flow, inlet temperature, outlet temperature, operating pressure, resistance, heat balance, core body size and other relevant parameters.

Team Support : Professional design team and technology team provide 24 hours service and 12 months warranty.

Factory Support : Accept sample order, economical and practical.

More service

1) We can help buyers design specific products or produce products according to buyers'design.

2) We can print logo according to buyers' requirement.

3) One year's warranty against B/L loading date. If you meet with quality problem, we promise to replace goods.

About EPS polystyrene moulding machine

Features of the machine:

1. Eps foam cutter With five working stations, 5 blocks can be put on the cutting line and in the same time 3 blocks will cut thickness, length, width cutting simultaneity, realized continuous operation, the capacity will be increased 100%;

2.There are several clamping device to improve the cutting accuracy;

3.Adopts aluminum alloy and aluminum profile for main frame with high strength, The block will move by chain transfer, it take strength engineering plastic for chain support, which keep cutting machine more accurate and last for a long time;

4.Stretch wrap machine is optional, it will be put in the end of cutting machine, it packs the EPS products after cutting to make transportation easy;

CE certificate, ISO9001:2008

WANLONG MACHINERY is a leading EPS polystyrene moulding machine supplier, factory, manufacturer that focuses on EPS polystyrene moulding machine. We focus on producing high-quality products with complete specifications. The quality of our products has passed international certification and the price is affordable.

EPS polystyrene moulding machine

When designing and developing new products according to customer needs, we strictly control quality standards while controlling production costs.