-

EPS auto batch pre-expander machine

-

EPS polystyrene foam beeds machine

-

EPS polystyrene foam beeds machine

-

EPS foam polystyrene moulding machine

-

EPS shape moulding machine

EPS continuous pre-expander machine

Port: Hangzhou, China

Production capacity: 20 sets / month

Payment method: Letter of credit, telegraphic transfer

Model:Automation

Computerized: Computerized

Certification: CE, ISO9001:2008

Condition: New

Add To Basket

Add To Basket

PDF:

EPS continuous pre-expander machine | EPS pre-expander machine | EPS machine supplier

1.The barrel is made of 304stainless steel, and the middle layer is heat insulation material. Reliable performance, higher productivity effect, low energy consumption;

2.The machine’s feeder system includes the first-phase and second-phase feeders, 680-type does not provide second-phase feeder;

3.Loading the EPS beads into the feeder, expansion of the EPS beads, the expanded EPS beads enter the fluidized bed (optional), and then go through the Centrifugal Fan and Conveying device to be transported into the Aging Silos, is to realize fully automatic production of EPS beads; the density range of foamed beads is 5-30g/L,(5-30kg/m³).

Owing to continuous development, we reserved the right for change any specification of machine without notice.

EPS continuous pre-expander machine

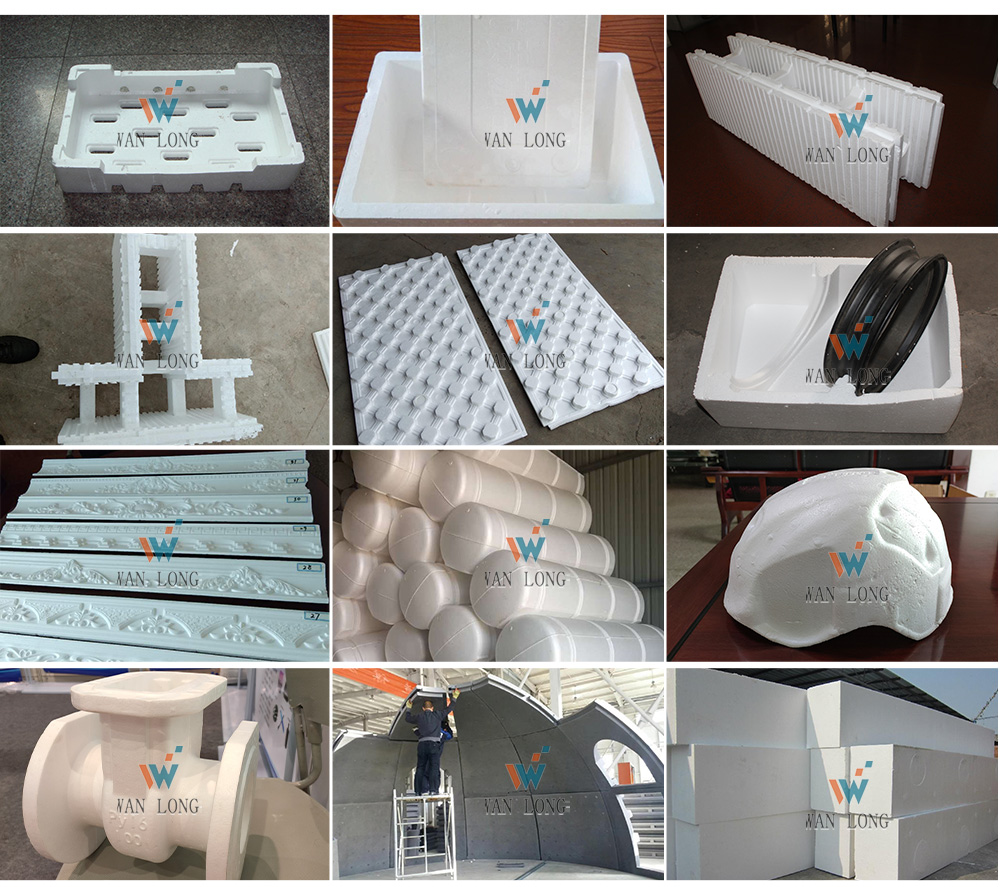

Application of the EPS continuous pre-expander machine

1.The machine uses electrical, pneumatic components, valves, etc. are well -known brand products, thus ensuring the operation of the machine stability, reliability and long service life.

2.Automatic discharge barrel using compressed air to blow the material, increase the feed rate.

3.The computer has a memory function, can often use the EPS raw material brands, specifications, foaming process, all parameters can be recorded in the computer. When you need to use the manufacturers of raw materials used in the past, you just press a computer touch screen can quickly go back to the original process.

WANLONG MACHINERY is a leading factory that focuses on EPS continuous pre-expander machine. We solemnly promise to provide your products with excellent quality, reasonable prices and the highest cost performance.

EPS continuous pre-expander machine

The quality of our products has passed international certification and the price is affordable.

| Items | Unit /Type | EPS-F-700 | EPS-F-900 | EPS-F-1200 | ||

| Expansion Barrel Size | mm | Ø 700*1700 | Ø 900*2000 | Ø 1200*2000 | ||

| Steam | Pressure | Mpa | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | |

| Inlet DN | mm | 20 | 20 | 40 | ||

| Consumption | Kg/h | 80-100 | 100-150 | 150-200 | ||

| Air-Compressed |

Pressure | Mpa | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | |

| Inlet DN | mm | 15 | 20 | 20 | ||

| Throughput | 4g/L |

Kg/h | 80-120 | 150-190 | ||

| 10g/L | 120-140 | 190-230 | ||||

| 15g/L | 100-120 | 140-170 | 230-270 | |||

| 20g/L | 120-150 | 180-220 | 280-320 | |||

| 25g/L | 150-170 | 230-270 | 360-420 | |||

| 30g/L | 200-220 | 280-320 | 450-550 | |||

| Density |

1st Expansion |

g/L | 12-30 | 12-30 | 12-30 |

|

| 2nd Expansion | 4-11 | 4-11 | 4-13 | |||

| Connected Load | kw | 7.92 | 8.92 | 13.33 | ||

| Overall Dimension |

Without dry bed | mm |

1800*1100*2700 |

1950*1300*3000 | 2200*1600*3100 | |

| With dry bed | 4700*2600*2700 | 4700*2700*3000 | 5000*3000*3100 | |||

| Weight | kg | 1400 | 1600 | 1800 | ||