-

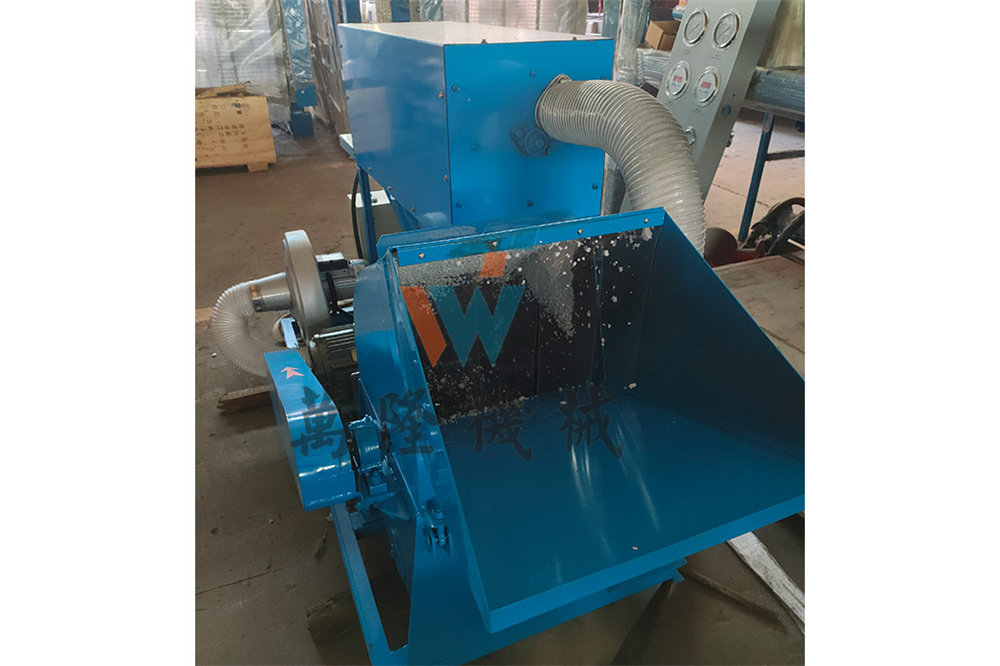

Grinder machine

-

Crusher de-dust machine

-

EPS crusher de-dust machine

-

Crusher machine

-

EPS polystyrene foam beeds machine

Central Vacuum System2

Port: Hangzhou, China

Production capacity: 20 sets / month

Payment method: Letter of credit, telegraphic transfer

Model:Automation

Computerized: Computerized

Certification: CE, ISO9001:2008

Condition: New

Add To Basket

Add To Basket

PDF:

Central Vacuum System machine | Vacuum System machine | System machine supplier

The central vacuum system is a professional equipment which is solve the problems of vacuum system on the moulding machine frequent start-up, resulting in the poor vacuum effect and the high maintenance rate of the vacuum pump.

The system adopts touch screen, PLC automatic control, and equipped with the main vacuum cylinder, condensing tank and draining barrel, which can be automatically turn on the vacuum pump according to the vacuum pressure set.

Almost eliminate the problem of impeller damage due to high resistance when pump starts working. The vacuum system can provide vacuum immediately when moulding machine is needed, which shortens the products cooling time, reduces the humidity of the product and improves the production efficiency.

About Central Vacuum System machine

Application of the Central Vacuum System machine

1.The machine adopts PLC programmable controller and touch screen control, automatic feeding, automatic electronic measurement, automatic control of temperature and pressure, dry barrel drums, etc., have made the material once completed, to ensure that the machine automatically cycle of production.

2.Automatic discharge barrel using compressed air to blow the material, increase the feed rate.

WANLONG MACHINERY is a leading Central Vacuum System machine supplier, factory, manufacturer that focuses on Central Vacuum System machine. We have our own production workshop and design team. If you cooperate with us, we can provide you with first-hand prices.

Central Vacuum System machine

No matter from which point of view, we are the best choice.

| Items | Unit | Type |

| Condenser | mm | ¢400-600x4500 |

| SS/Copper pipe | mm | ¢25 |

| Connected load |

kw |

30-50 |

| Vacuum |

Mpa |

-0.7 |

| Dimension |

mm |

5000x2000x6500 |

| Weight | kg | 6000 |