-

EPS auto batch pre-expander machine

-

EPS polystyrene foam beeds machine

-

EPS polystyrene foam beeds machine

-

EPS foam polystyrene moulding machine

-

EPS shape moulding machine

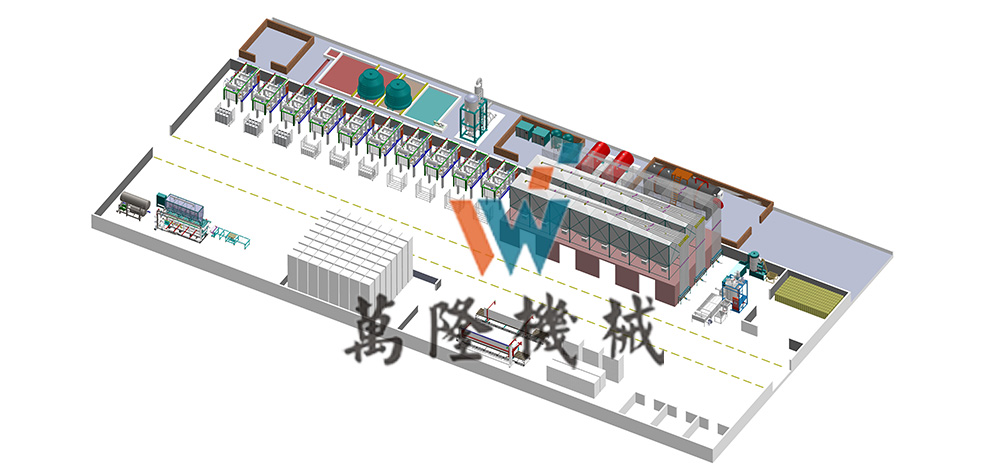

EPS Continuous Pre-expander Machine Factory

1. Inside and outside of barrel are both made of stainless steel, and the middle layer is heat preserving material, the production efficiency is 2~3 times higher than the average machine, it can reduce 25% energy consumption.

2. The baiting system includes first time baiting device and second time baiting device.

3. This machine can process secondary pre-expansion.

4. The expanded density range of foamed beads is 7~30 KG/M³,the density tolerance is minimal.

5. Steam pressure reducing valve is optional.

Add To Basket

Add To Basket

PDF:

EPS Continuous Pre-expander Machine Factory Manufacturers and Supplier - China Factory - WANLONG MACHINERY

EPS Continuous Pre-expander Machine Characteristics

1. Inside and outside of barrel are both made of stainless steel, and the middle layer is heat preserving material, the production efficiency is 2~3 times higher than the average machine, it can reduce 25% energy consumption.

2. The baiting system includes first time baiting device and second time baiting device.

3. This machine can process secondary pre-expansion.

4. The expanded density range of foamed beads is 7~30 KG/M³,the density tolerance is minimal.

5. Steam pressure reducing valve is optional.

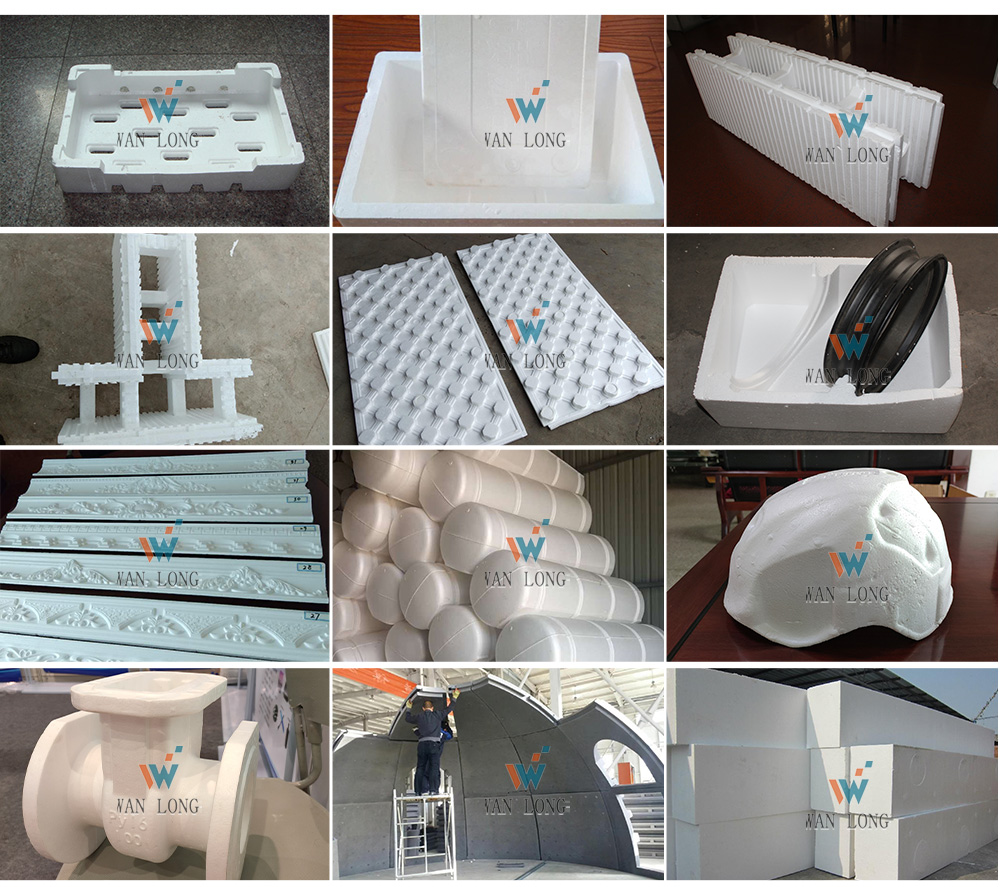

Auto Continuous EPS Pre-expander with first and second expansion for extremely lower density EPS foam products, especially beanbag filling. It's well-knit structure, less land occupation, convenient installation and easy operation.

EPS Continuous Pre-expander Machine Factory Manufacturers and Supplier

WANLONG MACHINERY is a leading China eps continuous pre expander machine factory supplier, with years experience in EPS machinery industry, offering you the most competitive price, better quality and long well service.

|

ITEM |

LWC700 |

LWC900 |

LWC1200Ⅱ |

|

|

Expansion Chamber |

Diameter |

DN700 |

DN900 |

DN1200 |

|

Volume |

0.6m3 |

1.2m3 |

2.2m3 |

|

|

Usable Volume |

0.4m3 |

0.8m3 |

1.5m3 |

|

|

Steam |

Entry |

DN25 |

DN25 |

DN50 |

|

Consumption |

80-100kg/h |

100-150kg/h |

150-200kg/h |

|

|

Pressure |

0.6-0.8Mpa |

0.6-0.8Mpa |

0.6-0.8Mpa |

|

|

Compressed Air |

Entry |

DN20 |

DN20 |

DN20 |

|

Pressure |

0.5-0.8Mpa |

0.5-0.8Mpa |

0.5-0.8Mpa |

|

|

Drainage |

Diameter |

DN20 |

DN20 |

DN20 |

|

Capacity |

15g/l 150kg/h |

15g/l 250kg/h |

7g/l 150kg/h |

|

|

20g/l 200kg/h |

20g/l 300kg/h |

10g/l 200kg/h |

||

|

25g/l 250kg/h |

25g/l 350kg/h |

|||

|

Connected Load/Power |

10KW |

10KW |

14KW |

|

|

Expanded Density |

7-25kg/m3 |

7-25kg/m3 |

7-12kg/m3 |

|

|

Overall Dimension |

4700*2660*2600mm |

4700*2900*3200mm |

4900*4650*3200mm |

|

|

Weight |

1400kg |

1600kg |

2000kg

|

|