Guide on eps block moulding machine

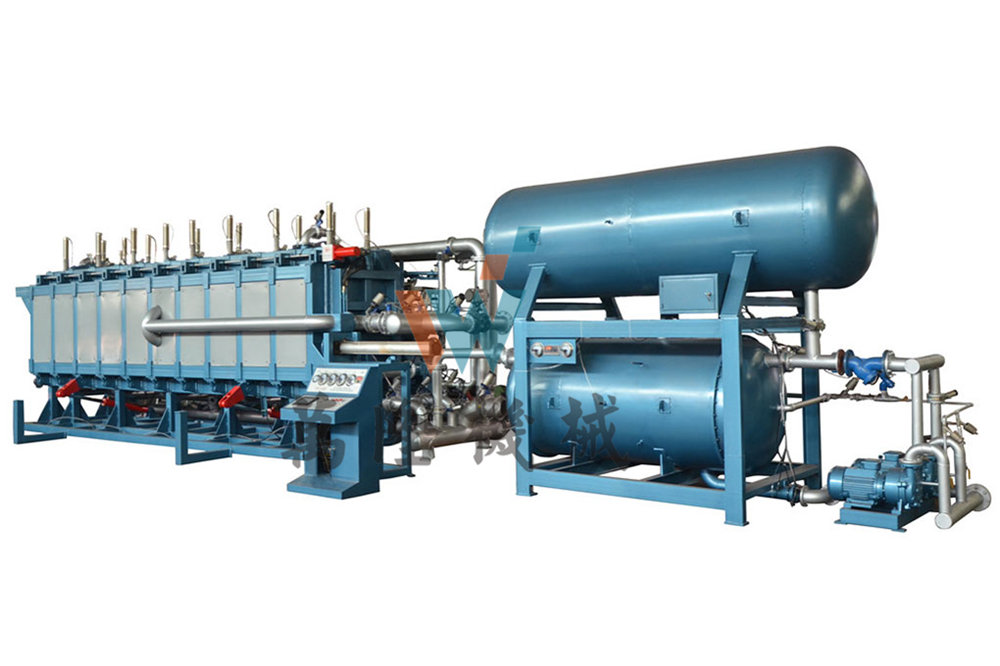

A block moulding machine is a machine that helps to make blocks of EPS, or expandable polystyrene. This type of machine is often used in the construction industry. EPS block moulding machines can be used to create blocks of various sizes and shapes.

A good EPS block moulding machine can help you to produce blocks quickly and easily. If you are looking for an EPS block moulding machine, this guide will help you to choose the right one. There are many factors to consider when purchasing an EPS block moulding machine, such as price, speed, and features. This guide will help you to find the perfect EPS block moulding machine for your needs.

how to maintain eps block moulding machine

EPS block moulding machine is one of the most important machines in EPS production line. It is very important to know how to maintain it properly so that it can work efficiently and last longer. The following are some tips on how to maintain your EPS block moulding machine:

- Keep the machine clean and free from dust and dirt.

- Check the oil level regularly and change the oil if necessary.

- Check the air filter and clean it if needed.

- Lubricate the moving parts of the machine regularly.

- Check for any loose bolts and nuts and tighten them if needed.

EPS block moulding machines are one of the most versatile machines in the EPS industry. They can be used to produce a wide variety of products, from packaging material to insulation boards. But like all machines, they need to be properly maintained in order to function properly and last a long time.

Common problems and solutions of eps block moulding machine

1. Common problems and solutions of EPS block moulding machine

2. The maintenace of EPS block moulding machine

3. How to operate EPS block moulding machine correctly

1. Vibration

2. Insufficient or uneven heating

3. Poorly designed or defective moulds

4. Inadequate or poor quality raw materials

5. Improperly adjusted cutting tools

EPS block molding machines are a type of machinery used in the manufacturing process of EPS products. As with any type of machinery, there are bound to be some problems that can occur during operation. Below is a list of some common problems that can happen, as well as their solutions:

1. Problem: The machine is not outputting any product.

Solution: Check to see if the raw materials are being fed into the machine properly. If they are, then check to see if the machine is set to the correct settings.

2. Problem: The machine is outputting products that are not the correct size or shape.

Solution: Check the settings of the machine to make sure that they are correct. If they are, then check the mold to see if it is the correct size and shape.

3. Problem: The machine is outputting products that have defects.

Solution: Check the settings of the machine to make sure that they are correct. If they are, then check the raw materials to see if they are defective.