A guide to polystyrene crushers

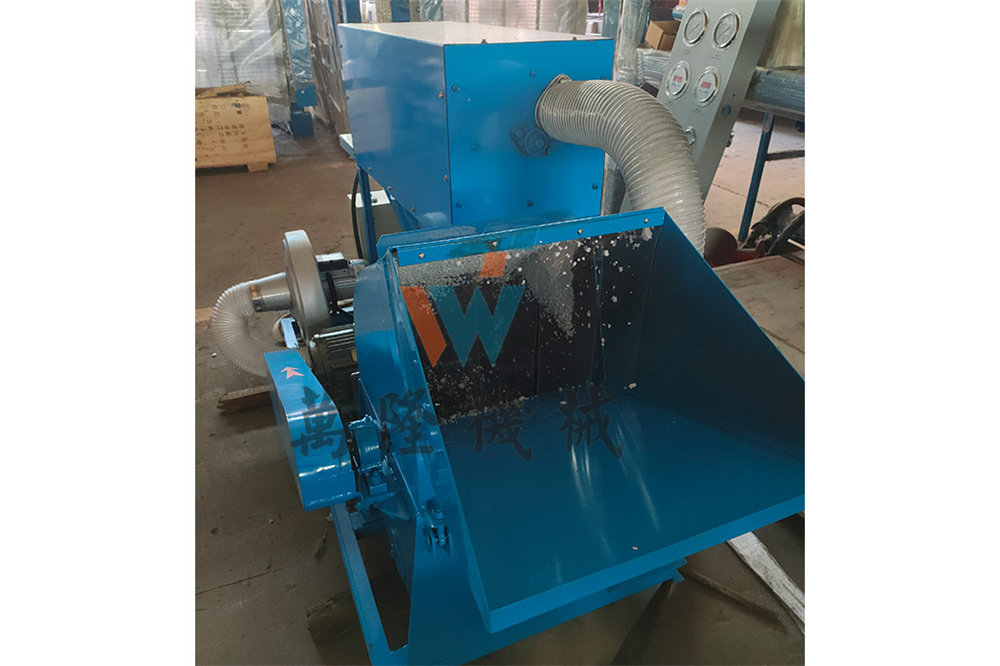

Polystyrene crushers can help reduce the volume of waste polystyrene foam products by up to 95%. They are simple to operate, safe and clean, and have a very low noise level. Polystyrene crushers are available in a wide range of sizes, from small handheld units to large industrial machines.

The most common type of polystyrene crusher is the jaw crusher. This type of crusher uses two plates, one fixed and one moving, to crush the foam material. The plates are usually made of steel or hard plastic. The moving plate is powered by an electric motor, and the fixed plate is attached to a frame.

Another type of polystyrene crusher is the rotary crusher. This type of crusher uses a rotating drum to crush the foam material. The advantage of this type of crusher is that it can be used for both large and small pieces of foam material.

How to maintain polystyrene crusher

1. Wash the crusher with mild soap and warm water.

2. Rinse the crusher with clean water.

3. Inspect the crusher for any cracks or damage.

4. Replace the crusher if necessary.

Polystyrene crusher is a machine that helps to crush waste polystyrene products and recycle them. It is important to maintain this machine so that it can work properly and last long. There are some tips on how to maintain polystyrene crusher:

Common problems and solutions of polystyrene crusher

Polystyrene Crusher is a machine used to reduce the volume of polystyrene foam. It is also known as EPS crusher. Polystyrene crusher can crush all kinds of polystyrene foam into granules with different sizes according to your requirements. The most common problem of polystyrene crusher is blockage.

The following are some solutions to the common problems of polystyrene crusher:

- If the machine is blocked by too much material, you can use a compressed air canister to clean the material inside the machine.

- If the blades of the machine are not sharp enough, you can sharpen them with a file or a grinding wheel.

- If the motor of the machine is overloaded, you can turn off the motor and let it cool down for about 30 minutes before turning it on again.

Polystyrene crusher is a machine that crushes polystyrene products into smaller pieces. It is widely used in the recycling industry to recycle polystyrene products. However, there are some common problems with polystyrene crushers that need to be addressed.

1. Polystyrene products are not properly crushed

This is the most common problem with polystyrene crushers. The reason for this problem is that the blades of the crusher are not sharp enough to properly crush the polystyrene products. As a result, the products are only partially crushed and they remain in their original shape.

2. Polystyrene products are not evenly crushed

Another common problem with polystyrene crushers is that they do not evenly crush the polystyrene products. This means that some parts of the product will be more crushed than others. This can be a problem if you need to use the product for different purposes.